Contract Packaging

Contract packaging provides packaging services for other companies to package and ship their products. All commodities require some sort of packaging, from food to cosmetics, and there are a wide variety of packaging types available to cater to different companies and products. Basically, a contract packager is a third party company that offers packaging solutions, and a contract packager can take care of everything from custom packaging to ensuring on-time delivery of the packaged goods.

Companies can use contract packaging for several reasons, but the most common one is efficiency. Many companies do not have the resources or materials to be able to package and transport their products in a cost-effective manner. They use these contract packaging services as a cheaper, easier option to ensure their product gets where they want it to go in the way that they want it to without having to do the work themselves.

Quick links to Contract Packaging Information

The History of Contract Packaging

While packaging goods have almost always been around in some form or another, the modern contract packaging industry did not become popular until the late twentieth century. The Contract Packaging Association, the national trade organization for this industry, was created in 1992, marking the rise of the industry. The contract packaging industry has actually doubled since 2008, proving to be a valuable resource for other companies and a strong industry in itself.

Further in the past, tinning, meaning the use of tinplate, was a common material used in early packaging mainly in the eighteenth century in England. This strategy was then followed by the technique of canning, which was first patented in 1810, and the first canning factory for commercial purposes was opened in London in 1812, setting the stage for a more modern packaging industry. Packaging with paper-based materials became more popular towards the late nineteenth century. Many of the new improvements for packaging stemmed from inventions and innovations intended for the U.S. military in transporting materials for wars like World War II, as weapons and food rations had to be packaged and moved securely so that the soldiers could effectively use them out in the field. There seems to be no clear consensus on the first company or figure that invented the contract packaging industry, but rather there is an accumulation of different companies and developments that helped the contract packaging industry become the success it is today. In fact, there are even degrees offered in packaging, with the first degree in Packaging Engineering offered in 1952.

Benefits of Contract Packages

Contract packaging services have already been established as a cost-effective solution for companies who simply do not have the resources or a facility to package, transport, or label their goods. Utilizing the contract manufactures of packaging allows for less investment on behalf of the company but a greater profit; the company does not have to spend as much time and money on packaging by outsourcing it but instead can allocate the saved money into increasing their own production. Similarly, this service allows for greater flexibility in businesses because they have more choices with contract packaging than they might if they had to figure out everything on their own. It also contributes to a quicker output and offers an easy option for short-term (like seasonal) packaging.

A major benefit is how contract packaging can be customized, creating a process that works for each company. Certain processes, like contact packagers that offer added services including bar coding, contract sewing, or thermoforming, work best for the companies that need them. It is necessary to evaluate the needs behind hiring the packaging contract service, judging if full-service turn-key solutions—meaning one that understands the entire supply chain—is the most practical option or if another, less compressive route should be taken.

How the Contract Packaging Process Works

Contract packaging works through classifying the packaging, and packaging can be considered primary, secondary, or tertiary. Primary packaging constitutes the material that comes into contact with the product, while secondary packaging contains multiple primary packages together. Lastly, tertiary packaging means the packaging used in handling products in bulk, storage in warehousing, and shipping. For example, if a food product is put in a glass jar, then the jar would be the primary packaging; the food comes into close contact with the jar. If these jars were then put together in a box, the box would be the secondary packaging. If these boxes were shrink-wrapped together, the shrink wrap would be a type of tertiary packaging. In addition, if the boxes were placed on or stored on a pallet in a warehouse, then that pallet would also be a type of tertiary packaging.

In order to even start the process, the contract packager must have the right material for the right product. One of the most common packaging materials is plastic because it is lightweight but durable. High-density polyethylene and polyethylene terephthalate are two of the sturdier plastics that are used for bottles. Flexible packing materials, like low-density polyethylene, are convenient for primary and secondary product packaging. Paperboard and fiberboard are also commonly used materials in both primary and secondary packaging. Paper is utilized for labels and thinner projects, while paperboard is thicker. Paperboard functions well as cartons and other primary packaging. Fiberboard, on the other hand, works well for secondary packaging with its rigid boards harboring more strength and resistance. Glass works well as a primary package to contain individual products, like glass jars or bottles. As for metals, the most common metal used in packaging is aluminum, used mainly for cans, containers, and aluminum foil. As aluminum retains both heat and cold fairly well and is extremely resistant to leaks, it functions as a solid apparatus for containing products. Foil can actually help keep commodities safe, protecting them from outside elements like sunlight and moisture that can harm them. In order to utilize these materials, certain machinery may also need to be available.

There are a variety of approaches contract packaging companies can take, and a company can even manage a portion of the client’s supply chain, meaning that they may source packing materials by delivery to the client’s sites of distribution. The whole process can be customized depending on the client's needs. While some clients may have the facilities to store large quantities of the product for short periods of time, they may not have easy access to a way to distribute their product to sell it. In consequence, a contract packager would help package the product in smaller, more appealing for retail containers to help the company sell their product. Fulfillment services can actually help with inventory management, creating a more practicable situation for companies and allowing more space for production. This type of service works with the organization of not only the production duties like material handling and controlling inventory for packaging and fulfillment but also assembly and transportation. Customization can also occur through packaging design. While there are certain designs for practicality that take into account cost, material, and usability, designs for aesthetic purposes can play a large role as well, particularly in the labeling of products. There are some services that even offer graphic design consultations to create labels that are more attractive to customers. Private labeling can be helpful for companies to create a more appealing purchasable commodity.

Contract Packaging Images, Diagrams and Visual Concepts

An example of what a contract packaging can produce.

An example of what a contract packaging can produce.

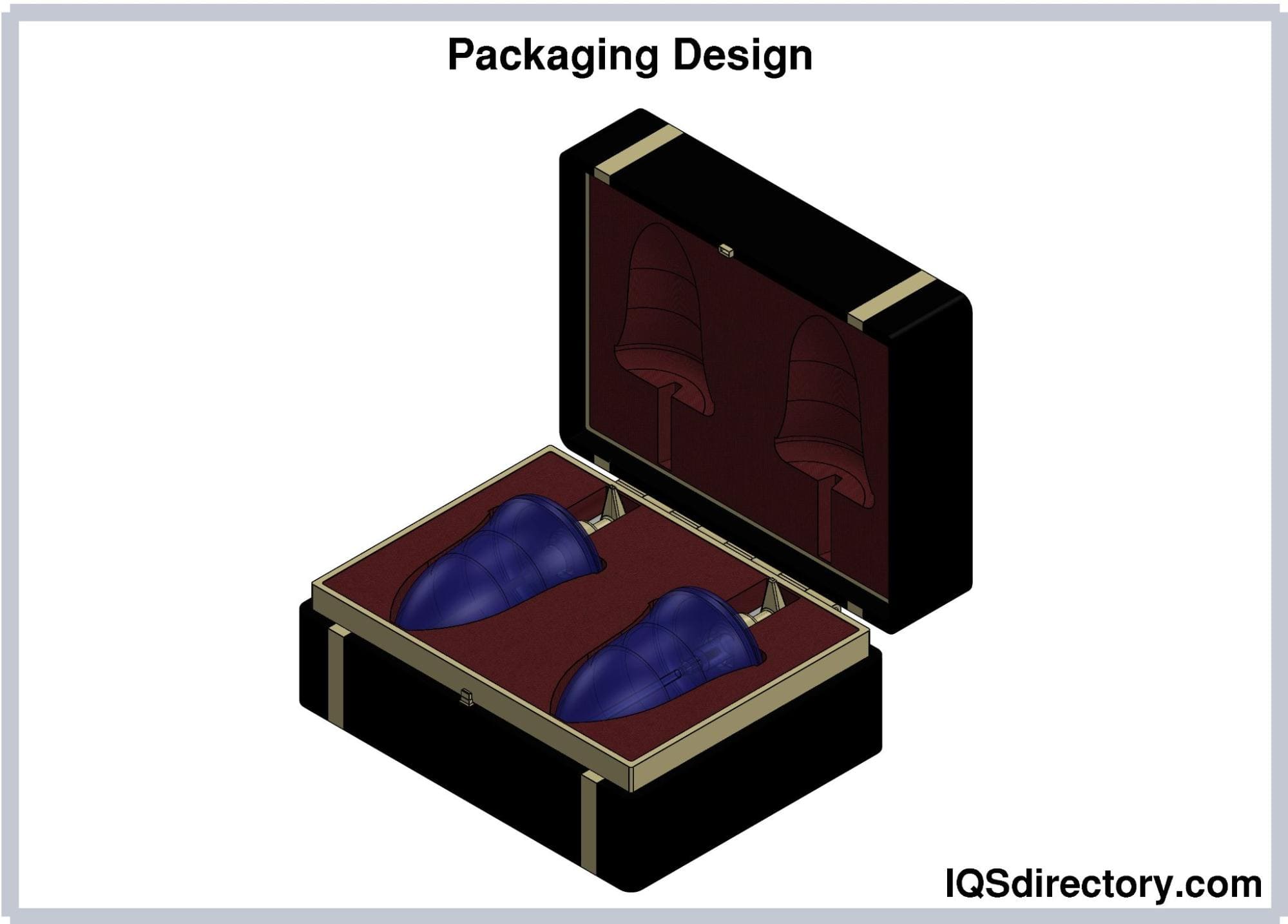

Packaging design considers brand graphics and packaging sizes in the contract packaging operations.

Packaging design considers brand graphics and packaging sizes in the contract packaging operations.

Blister packaging has an easy view of the product as it is placed between the two materials.

Blister packaging has an easy view of the product as it is placed between the two materials.

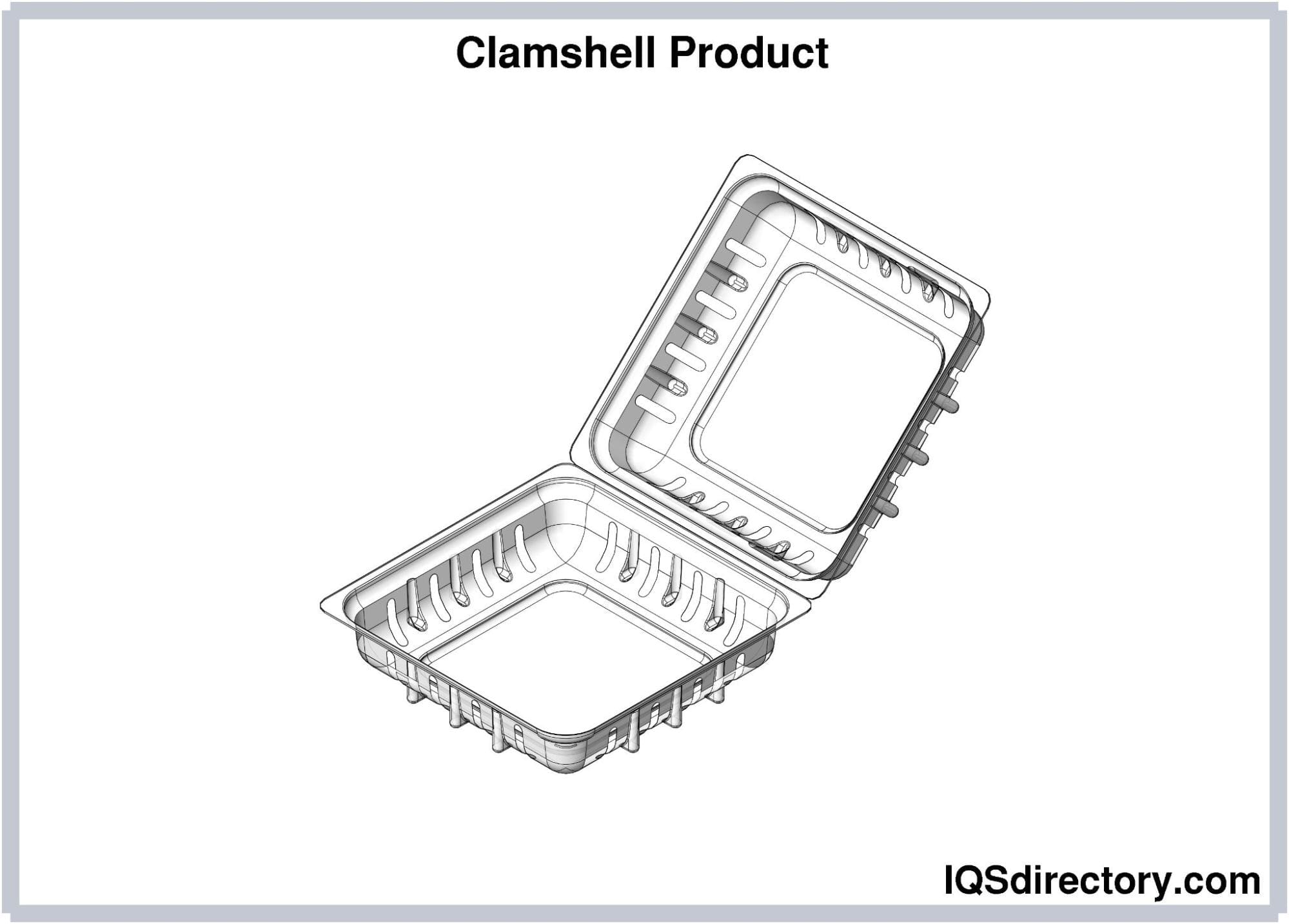

Clamshell packaging involves sealing a product within two preformed plastic sheets making it more tamper-proof.

Clamshell packaging involves sealing a product within two preformed plastic sheets making it more tamper-proof.

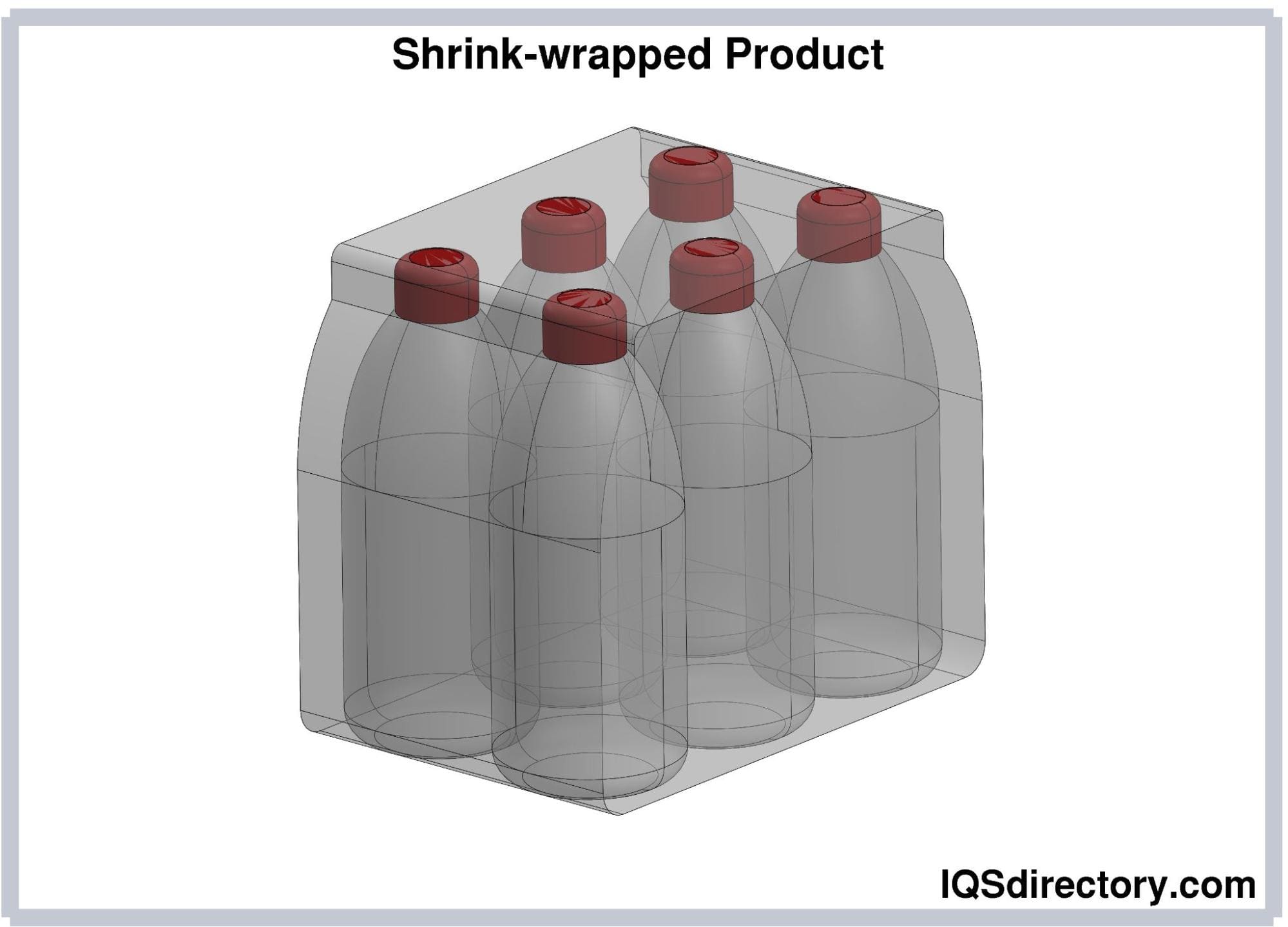

Shrink wrapping involves a plastic polymer film that is shrunk over a product as heat is applied to the shrink film, thus molding it around the product.

Shrink wrapping involves a plastic polymer film that is shrunk over a product as heat is applied to the shrink film, thus molding it around the product.

Contract Packaging Types

- Bench Assembly

- A hand-packaging technique in which items are on a bench and packaged accordingly.

- Blister Packaging

- Consists of a hard thermoformed bubble to hold the product to a back card for presentation.

- Cartoning

- The insertion of the product into the designed box, holder or enclosure for display and shipping.

- Clam Shell Assembly and Packaging

- The process of creating the plastic clam shells and inserting and sealing the items inside. Clam shell assembly is typically an automated process.

- Cosmetic Packaging

- Packaging used to store and ship skin care, beauty products and other cosmetic products.

- Custom Packaging

- Tailors packaging design to the needs of a specific product or company.

- Die Cutting

- Packaging process that produces a label shape using the cutting edge of a die.

- Food Packaging

- Any packaging material used for the shipment, storage or display of food products.

- Fulfillment Services

- Deal with the organization of various production duties, such as material handling, inventory control, assembly and transportation.

- Medical Packaging

- Any packaging used to store or transport medical devices or medication.

- Packaging Design

- The characteristics of a certain package.

- Packaging

- Any material used to enclose an item in order to protect it during shipment and while on display.

- Pharmaceutical Packaging

- The packaging of medical substances with regard to FDA regulations and requirements.

- Polybagging

- The placing of a product into a polybag and sealing it with heat.

- Product Packaging

- Material used to enclose a product in order to protect it during shipment and while on display.

- Radio Frequency

- RF (Radio Frequency) sealing is using radio frequency to permanently seal a clamshell package.

- Shrink Wrapping

- Common packaging method in which a product is wrapped in shrink film and then heated so that the film shrinks to the size and shape of the product. Shrink packaging provides a secure and tamper resistant layer.

- Skin Packaging

- Pulling a film tightly over a product that is on a card. Heat is used to adhere the film to the card and to create a transparent covering.

- Stretch Packaging

- A combination of blister, skin, clamshell and shrink wrapping, which is often seen with batteries and small toys.

Machines Used in Contract Packaging

Along with the materials that are commonly used in contract packaging, contract packagers need to have specific machines and tools in order to correctly package commodities. Although a few processes can be done by hand—like bench assembly, where items are placed on a bench and then packed by hand—many other packing techniques require the use of complex machinery. For example, blister packaging, seen frequently in packages of pharmaceutical pills, necessitates plastic molding equipment. Similarly, clam shell assembly and packaging needs a heat seal automated machine in order to safely seal the product. Other machines commonly used are label dispensers, form-fill-seal machines, and vacuum packaging machinery. In general, packaging machinery can be purchased as standard equipment, purchased customized, or even made or changed within the company itself, but because the machinery is so specific to the packaging industry, it is often easier for companies to subcontract their packaging needs than buy the machines themselves.

Products That Use Contract Packaging

There are a variety of contract packaging options available, so a large spread of industries use contract packaging services. Companies with food products often utilize contract packaging services. For example, while a company in the food industry may have the capabilities to produce the product, they may not have the ability to securely package and get it to the store in a condition appealing to customers. Contract packaging services can be helpful in providing secure food packaging, labeling and transportation so that the food product is not contaminated in the process and ends up on the shelves ready to be sold.

In addition, the cosmetic industry can be a popular customer for contract packaging services. Similar to goods in the food industry, cosmetics often need to be packaged in a particular way that they protect the product from outside contaminates and appeal to the customer, often through shape, color, and labeling. Many cosmetic products come in the form of powders, which can cause unique difficulties that contract packaging services have and experience dealing with, having different containers, pouches, and other solutions available. Medical or pharmaceutical companies also need safe packaging and storage for their products that contract packaging services can take care of, and companies in industries that produce industrial products and business-to-business products can also take advantage of contract packaging services as well.

Because many different industries use contract packaging, there are a variety of commodities that are produced by this process. With all the various industries that take advantage of contract packaging services, the products can range from makeup and beauty products to medicine to food and beverages. The food and beverage industry is one of the top industries that use these services along with the personal care and pharmaceutical industries, but in short, if a company needs a product packaged and transported, regardless of industry, there is likely a contract packaging service that can effectively meet their needs.

Things to Consider When Choosing a Contract Packager

There are many important factors to take into consideration when choosing a contract packaging service. The capability of a contract packager is most likely the most important because a contract packager needs to have the equipment and resources in order to package to the requirements. Searching or asking for a list of previous successfully completed projects may be helpful to confirm the capabilities. Location can impact delivery time and charges, and it can be more convenient to have a package located closer to the materials, end location, or distribution center. Flexibility may be something else to keep in mind in understanding how a company would handle any unforeseen difficulties or conflicts that may occur with a business. Overall, there are many qualified contract packaging services out there, and the key is to find the one that best fits with the needs of the company.

Contract Packaging Terms

- Adhesive

- A material capable of holding materials together by exterior attachment.

- Back Card

- A card, usually made of cardboard or paper, to which a product is mounted or secured for certain types of packaging, like blister or skin. Back cards can be custom printed and have special adhesives for product or other packaging elements.

- Bale

- A unit of compressed items or materials bound together with cord, strapping or metal ties. Bales may also be wrapped and bundled.

- Boxboard

- A term that refers to the differing grades of folding and scoring properties to create boxes. Boxboards are delivered to the contract packaging company in flat sheets.

- Clam Shell

- A plastic packaging device with two sides and a folding hinge, which encloses and seals an item inside like a clam.

- Can

- A small primary packaging item, usually made of metal.

- Closure

- The means by which a container is sealed and its contents retained.

- Collating

- The sorting and/or assembly of items.

- Contract Assembly

- Hirable services for the construction or gathering of a product.

- Corrugated

- A term that refers to paper-based board that has one or more sheets of fluted paper glued to one or more flat sheets of board.

- Die

- Any of a variety of tools or devices used for cutting material to a desired shape.

- FDA (Food and Drug Administration)

- An organization that sets standards and regulations for the packaging of food.

- Gloss

- A shiny finish on a smooth surface, such as vinyl or paint.

- Hand Assembly

- The putting together of products through manual labor or the combination of manual and automated labor.

- Heat Sealing

- A process in which heat is used to fasten together two substrates.

- Jar

- Small, hard packaging that has a wide mouth and is made typically of glass, ceramic or plastic.

- Outsourcing

- Sending a product to a contract supplier, packager or assembler for their services.

- Pack Out

- The last step for a product before it is shipped out.

- Pick & Pack

- A shipping term for taking a product from inventory and packing it and preparing it for shipping.

- Relabeling

- Putting a new label over an old label on a product or replacing the existing label with a new label.

- Reverse Logistics

- Processing returned goods and reworking or repackaging them to new standards.

- Screen Printing

- A process of printing in which the ink is forced through the image area of a properly stretched fabric by the use of a squeegee or, in some cases, air pressure directly onto the surface to be printed.

- Secondary Operation

- An action that must be performed following the line process, as it needs special attention.

- Strapping

- A flexible piece of strip material that is normally flat or circular in cross section, and is used as reinforcement in a larger bale or bundle or to secure items for packaging within a container.

- Stretch Wrap

- Material that expands when applied under pressure and recovers while conforming to the item packaged.